Technical Specifications

| Part Name | Terex Demag CC2500 Track Rollers; Lower Rollers; Bottom Rollers |

| Material Grade | G22NiMoCr5_6, 28CrMnMo, 31Mn2SiMo, 31Mn2SiMoNi |

| Production Process | Casting, whole quenching & tempering, then surface hardening. |

| Quality Standards | ISO 9001, SGS |

| Brand | EG |

| Warranty | 1 year or 2500 working hours |

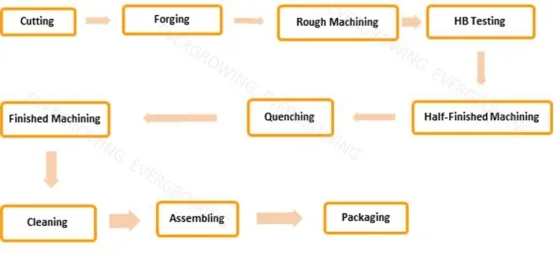

The Production Process for the CC2500 track rollers:

Advantages

- Material Excellence:

EG uses advanced high-strength steel alloys with added elements such as Si, Mn, Mo, Cr, etc., which have excellent wear resistance and ensure that the chassis components can withstand harsh operating conditions. This material has strong fatigue resistance, which can extend the overall service life of the Terex Demag CC2500 Track Rollers.

- Strict Quality Control:

EG crawler crane undercarriage parts are manufactured to meet or exceed international quality standards and certifications such as ISO 9001 and CE certification, ensuring consistent quality and safety of all production units.

- Precision Dimensions:

We produce according to original factory drawings and focus on manufacturing undercarriage parts with precise dimensions to ensure perfect fit and compatibility with the overall crane structure. This reduces downtime and helps improve the performance and efficiency of the machine.

Production Process of Terex Demag CC2500 Track Roller

- Forging: Die forging is suitable for small parts, improving material efficiency and speed; free forging is suitable for larger parts, but it is inefficient.

- Rough machining: Using a lathe to remove excess material.

- Normalizing: A heat treatment process to improve material properties.

- Quenching: Hardening the material by rapid cooling.

- Case hardening: Local hardening of the surface using induction heating.

- Welding: Joining parts using friction welding or argon arc welding.

- Finishing: Precision machining to obtain size and smooth surface.

- Assembly: Assembling parts into the final product.

- Painting: Applying a protective coating.

- Packaging: Final packaging for shipping.

FAQ:

- What’s the main product in your company?

Our main product is Crawler Crane Undercarriage Parts (crane track shoe, bottom roller, top roller, idler, sprocket, and track chain assy).

- How can I be sure the part will fit my crane?

Please notify us your crane model, part numbers, or confirm the dimensions.

- What about your Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

- Do you provide OEM developing services?

Yes, customer’s OEM is welcome, we have plenty experience in OEM developing.

Big orders get special discounts. Email us to chat with our experts now!

Reviews

There are no reviews yet.