Terex Demag CC1000 Crawler Crane Alternative Options:

The undercarriage components of the Terex Demag CC1000 crawler crane are designed for stable travel and reliable lifting performance under demanding working conditions. The track shoes are the primary ground contact components, providing powerful traction and effectively distributing weight, thus enhancing the crane’s stability on various surfaces.

The track shoes are mounted on a complete track system, which includes matching track chains, pins, and bushings for smooth articulation and continuous movement. This structure ensures that the tracks remain flexible while withstanding high working loads and have a long service life.

The track rollers support the weight of the crane and guide the track chain along the track frame, helping to maintain proper alignment and smooth travel.

The idler wheels stabilize the upper track path, reducing vibration and uneven wear during operation.

The drive sprockets transmit driving force from the final drive to the track chain, enabling precise control and accurate positioning on site.

The idler wheels guide and tension the track system, helping to prevent track derailment and extending the lifespan of the entire undercarriage.

Together, these CC1000 undercarriage components enable balanced load distribution, controlled wear, and reliable performance, making them suitable for component replacement, overhauls, or long-term crane operation in heavy-duty lifting projects.

Technical Specifications

| Parameter | Details |

| Material Grade | G22NiMoCr5_6, 28CrMnMo, 31Mn2SiMo, 31Mn2SiMoNi |

| Production Process | Casting, whole quenching & tempering, then surface hardening. |

| Quality Standards | ISO 9001, SGS |

| Brand | EG |

| Warranty | 1 year or 2500 working hours |

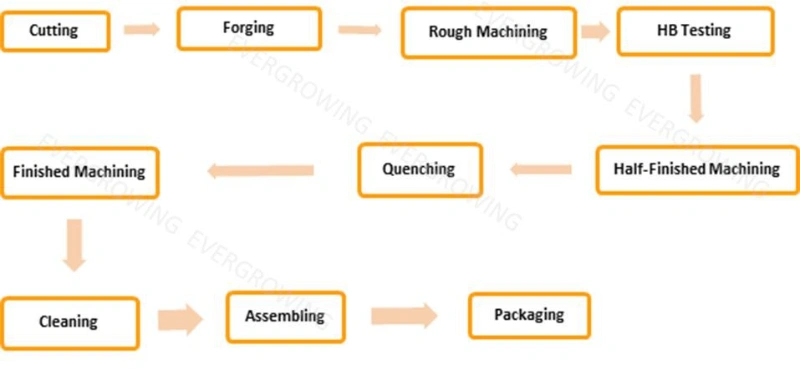

The Production Process for the Terex Demag CC1000 track shoes:

Advantage

- Material Excellence:

The materials are selected for their ability to withstand corrosion, ensuring a longer life cycle, especially in challenging environments such as coastal or industrial sites with exposure to moisture and chemicals.

- Strict Quality Control:

EG components are manufactured to meet or exceed international quality standards and certifications such as ISO 9001 and CE certification, ensuring consistent quality and safety in all units produced.

- Advanced Production Processes:

Certain components, such as track chains and rollers, undergo heat treatment processes to improve hardness and wear resistance. This enhances their ability to perform in extreme conditions.

- Long-Term Durability and Performance:

With superior design and material selection, EG components require less maintenance compared to traditional components, reducing downtime and increasing the operational efficiency of the crawler crane.

Cast Terex Demag CC1000 Track Shoes

The Foundation of Unstoppable Crane Performance

We deliver mission-critical components that combine metallurgical expertise with rugged engineering. Every track shoe is a result of 50+ iterations to achieve the perfect balance of strength, weight, and terrain adaptability.

FAQ:

- What’s the main product in your company?

Our main product is Crawler Crane Undercarriage Parts (crane track shoe, bottom roller, top roller, idler, sprocket, and track chain assy).

- How can I be sure the part will fit my crane?

Please notify us of your crane model, part numbers, or confirm the dimensions.

- What about your Quality Control?

We have a perfect QC system for the perfect products. A team that will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety in the container.

- Do you provide OEM development services?

Yes, customers’ OEM is welcome; we have plenty of experience in OEM development.

Big orders get special discounts. Email us to chat with our experts now!

Reviews

There are no reviews yet.