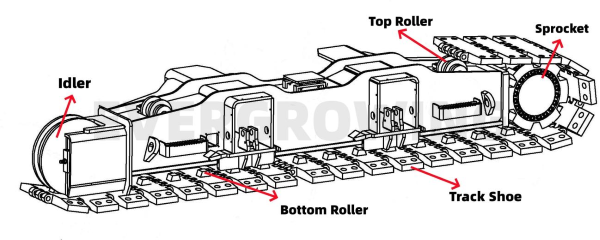

Manitowoc 4600S crawler crane track shoes are a key component to ensure the crane performs optimally and maintains stability in a variety of challenging environments. Designed with durability in mind, these track shoes provide excellent traction, stability and load distribution on soft or uneven terrain.

Product Information

| Parts Name | Manitowoc 4600S Track Shoe; Manitowoc 4600S Track Pad; Manitowoc 4600S Track Plate; Manitowoc 4600S Crawler Shoe |

| Material | 35SiMn/ 28CrMnMo/ 28CrMnMoNi |

| Technique | Casting |

| Brand Name | EG |

| Colors | Black/ Customers Requirement |

| Country of Origin | China |

| Warrantly | 1 Year/ 2500 Working Hours |

Here are some key features of the track shoes:

- Material and construction: The track shoes are made of high-strength steel for durability and wear resistance under heavy loads and harsh conditions. They are designed to withstand extreme pressures, ensuring the crane operates smoothly even in the harshest environments.

- Design: The design of the track shoes improves the performance of the crane by ensuring even weight distribution across the surface. This design also reduces the risk of the crane sinking into soft soil or mud, provides better stability and reduces the frequency of maintenance.

- Compatibility: The track shoes are designed and produced according to the original factory drawings to ensure perfect fit and compatibility with the crane chassis. This ensures maximum efficiency and safety during operation.

- Durability and maintenance: The solid construction of the track shoes ensures a longer service life and lower maintenance costs. Track shoes perform well under heavy use, and regular inspections ensure they continue to operate at peak efficiency.

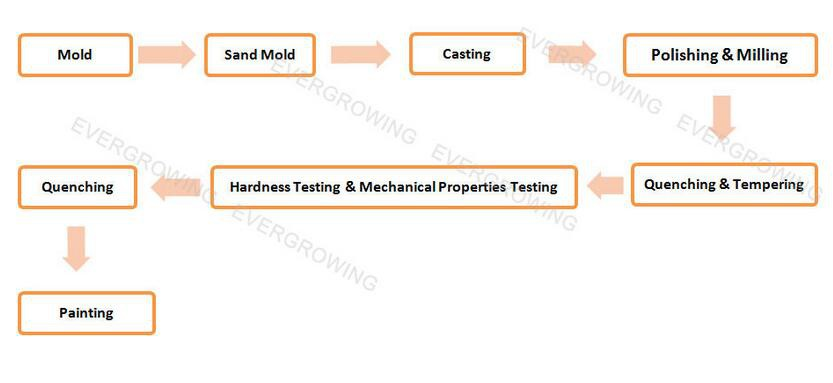

The production process of Manitowoc 4600S track shoes:

- Mold: Make a casting mold suitable for track shoes to ensure the accuracy of size and shape.

- Sand Mold: Use sand mold to surround the mold to form the shell required for casting.

- Casting: Pour the metal liquid into the sand mold for casting, and take samples for chemical composition analysis to ensure material quality.

- Rough machining: Remove excess material through polishing and vertical pipe milling, and perform sand removal to prepare for further processing.

- Normalizing: Normalize the casting to improve the material’s organizational structure and enhance its mechanical properties.

- Quenching & Tempering: After quenching the casting, temper it to increase hardness and toughness.

- Polishing: Perform surface polishing to improve the appearance and surface quality of the track shoe.

- Hardness Testing & Mechanical Properties Testing: Test the hardness and mechanical properties of the track shoes to ensure that they meet the requirements.

- Surface Quenching: Quench the surface of the track shoes to improve the surface hardness and wear resistance.

- Painting: Paint the track shoes to prevent corrosion and improve the appearance quality.

Manitowoc Available Model

| M50 | M50-W | M65 | M80 | M85 | M222 | M222EX |

| M250 | M555 | M777 | M888 | M999 | M999C | 2250 |

| 3900 | 3900W | 4000 | 4100 | 4100W | 4100S | 4500 |

| 4600 | 4600S | 6400 | 8000 | 8500 | 10000 | 11000 |

| 11000-1 | 12000 | 14000 | 16000 | 18000 | MLC165 | MLC300 |

If you need Manitowoc 4600S track pads, feel free to contact us.

We offer high-quality products that meet your specifications and ensure durability for your machinery. Contact us today for more information or to place an order. We’re here to help!

Reviews

There are no reviews yet.