Product Details

| Product Information | Manitowoc 4100S Track Roller; Manitowoc 4100S Bottom Roller; Manitowoc 4100S Lower Roller |

| Material | 35SiMn/ 28CrMnMo/ 28CrMnMoNi |

| Technique | Forging |

| Brand Name | EG |

| Condition | New |

| Warrantly | 1Year/ 2500 Working Hours |

The Manitowoc 4100S crawler crane is a versatile and powerful machine for heavy lifting and construction applications. It is designed for lifting, positioning and moving large loads in a variety of industries, including construction, oil and gas, and infrastructure development. The Manitowoc 4100S has a maximum lifting capacity of 275 tons. This makes it suitable for a variety of demanding lifting tasks, such as lifting heavy components for industrial plants, steel structure installation, and other construction projects.

Advantages

- Material Excellence:

EG uses advanced high-strength steel alloys with added elements such as Si, Mn, Mo, Cr, etc., which have excellent wear resistance and ensure that the chassis components can withstand harsh operating conditions. This material has strong fatigue resistance, which can extend the overall service life of the Manitowoc 4100S Track Rollers.

- Strict Quality Control:

EG crawler crane undercarriage parts are manufactured to meet or exceed international quality standards and certifications such as ISO 9001 and CE certification, ensuring consistent quality and safety of all production units.

- Precision Dimensions:

We produce according to original factory drawings and focus on manufacturing undercarriage parts with precise dimensions to ensure perfect fit and compatibility with the overall crane structure. This reduces downtime and helps improve the performance and efficiency of the machine.

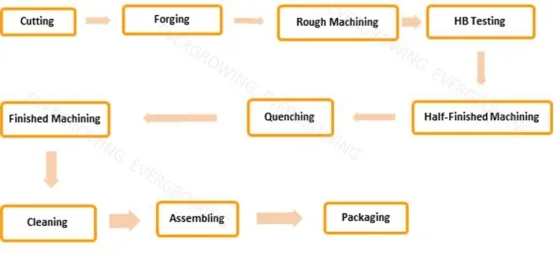

Production Process of Manitowoc 4100S Track Roller

- Forging: Die forging is suitable for small parts, improving material efficiency and speed; free forging is suitable for larger parts, but it is inefficient.

- Rough machining: Using a lathe to remove excess material.

- Normalizing: A heat treatment process to improve material properties.

- Quenching: Hardening the material by rapid cooling.

- Case hardening: Local hardening of the surface using induction heating.

- Welding: Joining parts using friction welding or argon arc welding.

- Finishing: Precision machining to obtain size and smooth surface.

- Assembly: Assembling parts into the final product.

- Painting: Applying a protective coating.

- Packaging: Final packaging for shipping.

Manitowoc Available Model

| M50 | M50-W | M65 | M80 | M85 | M222 | M222EX |

| M250 | M555 | M777 | M888 | M999 | M999C | 2250 |

| 3900 | 3900W | 4000 | 4100 | 4100W | 4100S | 4500 |

| 4600 | 4600S | 6400 | 8000 | 8500 | 10000 | 11000 |

| 11000-1 | 12000 | 14000 | 16000 | 18000 | MLC165 | MLC300 |

Reviews

There are no reviews yet.