Our crawler crane undercarriage parts have a wide range of applications and can be matched with cranes of different tonnages. No matter what tonnage of undercarriage parts you need, we can provide them.

Technical Details of Manitowoc 18000 Crawler Crane Track Pads:

| Material | 31Mn2Si, 28CrMnMo |

| Package Detail | Export Standard Pallet/ Plywood Case |

| Trade Terms | EXW, FOB, CFR, CIF |

| Technology | Casting |

| Heat Treatment | Whole Quenching and Tempering, then Surface Hardening |

| Advantage | Comprehensive Service System; Professional Research Team; Advanced Production Equipment; Superior Material; Strict Quality Control |

| Color | Black / Customer Requirement |

| Brand Name | EG |

| Warranty | 2500 Working Hours / One Year |

| Inspection Method | MT, UT… |

| Min Order Quantity | 1 Piece |

| Port of Loading | Qingdao, China |

| Payment | T/T, L/C… |

| Place of Origin | Shandong, China |

| Certification | ISO9001 |

Our Advantages:

Comprehensive Support Services; High Quality Production Materials; Professional Research Team; Rich Production Experience; Superior Material; OEM Quality; Advanced Production Equipment.

Products can be customized according to customer needs.

We has passed the ISO9001 certification.

Long Warranty Period: 2500 Working Hours / One Year

Professional Inspection Method: MT, UT…

2 pcs track pins and 2 sets bolt & nuts per track pad. We can provide them if the customer needs them.

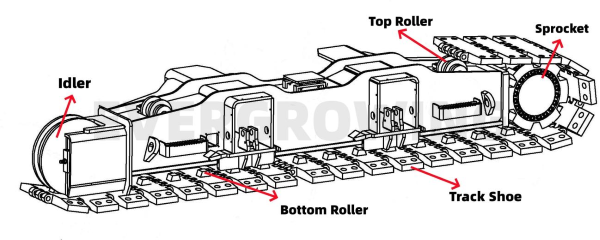

Crawler Drive Tumbler: planetary driven tumbler transmits drive torque to crawler tread. tumbler is supported at both ends by crawler frame.

Production Process of Manitowoc 18000 Track Shoes

Mold → Sand Mold → Casting → Polishing & Milling → Quenching & Tempering → Hardness Testing & Mechanical Properties Testing → Quenching → Painting → Packing

Reviews

There are no reviews yet.