Technical Details:

The track plate is a conveying part that surrounds the bottom rollers, top rollers, sprocket, idler, on which the machine moves. Track pads provide a working platform for crane, and track pads are in contact with the ground, thus providing traction for the crane to move. Our company is committed to creating high quality track pads to provide customers with quality service.

| Material | 35SiMn, 35SiMnRe, 31Mn2Si, 28CrMnMo, 28CrMnMoNi |

| Technology | Casting |

| Heat Treatment | Whole Quenching and Tempering, then Surface Hardening |

| Advantage | Superior Material; Strict Quality Control; OEM Quality; Large Stock |

| Color | Black/ Customer Requirement |

| Brand Name | EG |

| Warranty | 1 year / 2500 working hours |

Advantages:

- Professional Research Team; Rich Production Experience; Superior Material; OEM Quality; Advanced Production Equipment; Comprehensive Support Services; High Quality Production Materials

- Products can be customized according to customer needs.

- We has passed the ISO9001 certification.

- Warranty Time: 2500 Working Hours / One Year

- Professional Inspection Method: MT, UT…

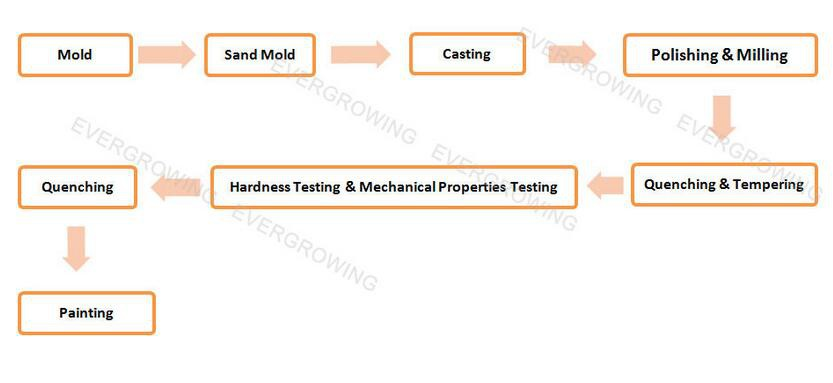

Production Process of IHI Crane Track Plate:

- Mold- Sand mold-Casting-Polishing&Milling-Quenching&Tempering-

- Hardness Testing&Mechanical Properties Testing-Quenching-Painting-

- Package&Packing

IHI Crane Track Plate We Can Produce:

| CH350, CH400, CH500, CH800, CCH300, CCH300T, CCH350, CCH350-D3, CCH400, CCH500, CCH500-2, CCH500-3, CCH500-3 II, CCH500-T, CCH500EX, CCH550, CCH650, CCH700, CCH700-3II, CCH800, CCH800-2, CCH900, CCH1000, CCH1000-5, CCH1200, CCH1200-5, CCH1500, CCH1500E, CCH1500-3, CCH1800, CCH2000, CCH2000-5, CCH2500, CCH2800, DCH650, DCH700, DCH800, DCH900, DCH1000, DCH1200, K300, K400A, K400B, K1000, IPD100, IHI 6020, etc. |

Technical And Testment Of IHI Crane Track Plate:

OEM Service:

We are very supportive of customisation and have a dedicated design team to help. We understand that every customer’s needs are unique, so we are committed to offering customisation options for our products, including materials, sizes, colours and more.

- We understand that different industries have different needs for crawler crane chassis parts, so we can provide the most suitable material options for our customers’ specific application scenarios.

- We can provide different sizes of products according to customers’ requirements. With advanced production equipment and technology, we can customise production according to the size requirements provided by customers. Whether it is small-sized crawler crane chassis parts or large-sized complex structures, we can meet customers’ needs.

- We also offer a wide range of colour options according to customers’ requirements. We have advanced coating equipment and technology to customise the colour during the product manufacturing process. Customers can choose the right colour according to their brand image or specific needs.

Reviews

There are no reviews yet.