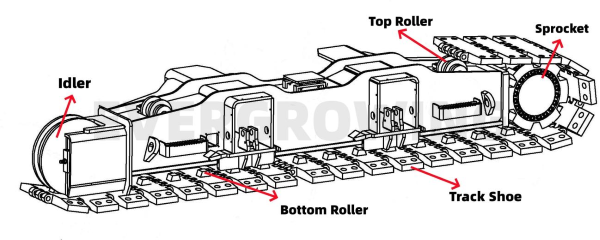

The IHI CCH2000-5 Crane Sprocket (Drive Wheel) is a critical component in the undercarriage system of crawler cranes, responsible for transmitting power from the final drive to the track chain, ensuring smooth and efficient movement. Our EG brand sprockets, specifically designed for the IHI CCH2000-5 crawler crane, are manufactured using high-strength steel and advanced casting processes. These sprockets deliver long-lasting performance in construction, foundation drilling, heavy lifting, and mining applications.

Technical Details:

| Material | 35SiMn, SCSiMn2H, ZG40Mn2, |

| Technology | Casting |

| Heat Treatment | Whole Quenching and Tempering, then Surface Hardening |

| Advantage | Superior Material; Strict Quality Control; OEM Quality; Large Stock |

| Color | Black / Customer Requirement |

| Brand Name | EG |

| Warranty | 2500 Working Hours / One Year |

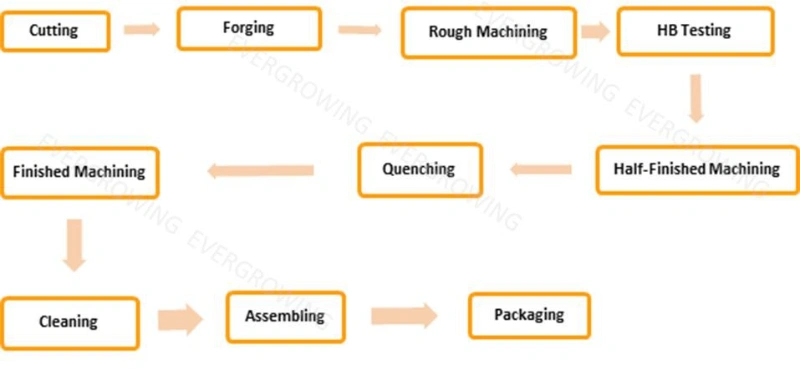

Production Process:

Why Choose Our Drive Sprockets?

- Longer Service Life– Made from premium steel and heat-treated for optimal hardness, our sprockets resist wear and fatigue, significantly reducing the need for frequent replacement.

- Reduced Downtime – Precision-machined tooth profiles ensure perfect engagement with the track chain, minimizing vibration and load stress, and supporting consistent field performance.

- Cost-Effective – We offer the same quality level as original parts, but at more competitive pricing. Ideal for both aftermarket and replacement purposes.

- Global Shipping– We maintain inventory of commonly used IHI sprockets, including the CCH2000-5 model, allowing quick order turnaround and global shipping.

IHI CCH2000-5 Crane Sprocket We Can Produce:

| CH350, CH500, CH800, CCH300, CCH350, CCH350-D3, CCH400, CCH500, CCH500-2, CCH500-3, CCH500-3 II, CCH500-T, CCH500EX, CCH550, CCH650, CCH700, CCH800, CCH800-2, CCH1000, CCH1000-5, CCH1200, CCH1500, CCH1500E, CCH1800, CCH2000, CCH2500, CCH2800, DCH650, DCH700, DCH800, DCH900, DCH1000, DCH1200, K300, K400A, K400B, K1000, IHI PD100, IHI 6020 etc. |

Maintenance Tips:

– Regular Inspection – Look for signs of uneven wear, cracks, or misalignment that could indicate underlying issues.

– Proper Lubrication – Follow manufacturer guidelines for grease intervals.

– Track Tension Adjustment – Incorrect tension can cause excessive stress on both the sprocket teeth and track links. Regularly check and maintain optimal tension settings.

Reviews

There are no reviews yet.