American 700 Series Track Rollers Key Characteristics:

- Type: Lattice boom crawler crane.

- Manufacturer: American Hoist & Derrick (Amhoist).

- Era: Popular in the mid-to-late 20th century.

- Features: Heavy-duty design, tracked mobility, used for large construction and industrial lifting.

- Legacy: Parts and support for these older machines are still maintained by specialized crane service companies.

Composition:

Lower roller body, Brass Bushing, Shaft, Caps, Floating Seal, O-rings.

Function:

For the American 700 series crawler cranes, the track rollers are a core component of the undercarriage system, designed to ensure stable operation under high loads and extended work cycles. They are meticulously engineered to meet the demands of heavy lifting capacities and complex construction site conditions.

The track rollers help maintain precise track alignment and stable track height, ensuring the crane remains level during travel and lifting operations. This stability is crucial when using heavy counterweights, long boom systems, or operating on uneven ground conditions.

By distributing the load evenly across the track frame, the track rollers reduce localized stress on the track chain and surrounding structures. This controlled load transfer enhances the durability of the undercarriage and ensures reliable operation throughout its service life.

The track rollers also contribute to enhanced motion control and positioning accuracy on site. The stable and smooth track movement allows for precise crane positioning, which is essential for safe lifting operations in confined or complex work environments.

Technical Details:

| Material | 40Mn2 |

| Place of Origin | Shandong, China(Mainland) |

| Heat Treatment | Whole Quenching and Tempering, then Surface Hardening |

| Advantage | Comprehensive Service System; Professional Research Team; Advanced Production Equipment; Superior Material; Strict Quality Control; OEM Quality |

| Packaging | Export Standard Pallet/ Plywood Case |

| Trade Terms | EXW, FOB, CFR, CIF |

| Technology | Forging |

| Warranty | 2500 Working Hours / One Year |

| Inspection Method | MT, UT… |

| Min Order Quantity | 1 Piece |

| Port of Loading | Qingdao, China |

| Payment | T/T, L/C… |

| Certification | ISO9001 |

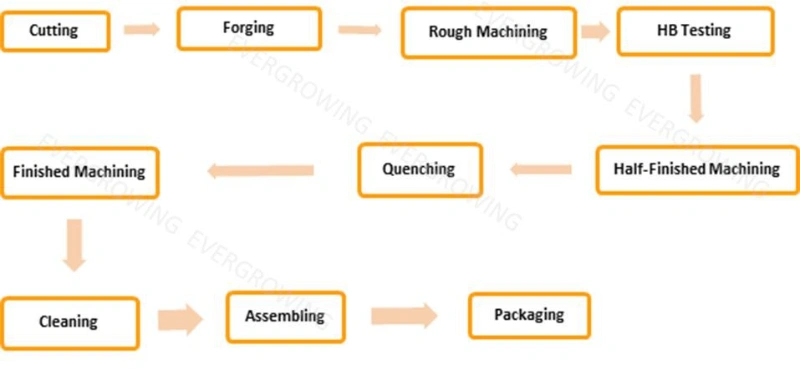

Production Process of American 700 Series Track Rollers:

Cutting – Forging – Rough Machining – HB Testing – Half-finished Machining – Quenching – Finished Machining – Cleaning – Assembling – Packaging

Our Market

Our products are exported to all over the world, and have been widely praised by customers.

Reviews

There are no reviews yet.