Link-Belt Undercarriage Parts

Product Overview

Product Specifications

LS218HII

LS248H

LS308H

LS218HSL

LS248HII

LS318

LS218HSL-C5

LS248HSL

LS338

LS228HSL

LS248H5

LS348

LS238H

LS278H

LS348H5

LS238HSL

LS298HSL

Produce Process

Track Shoe Machining

Grinding the surface of the track pad to remove sand and impurities, ensuring a smooth product surface with good performance.

Track Roller Quenching

The track roller undergoes a quenching process to enhance its wear resistance, improving durability in harsh working conditions.

Pin Machining

The pin is precision machined to achieve the correct size and surface finish for optimal function and service life.

why choose us?

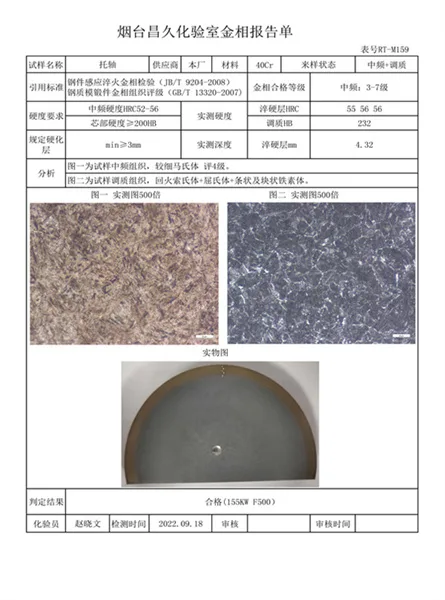

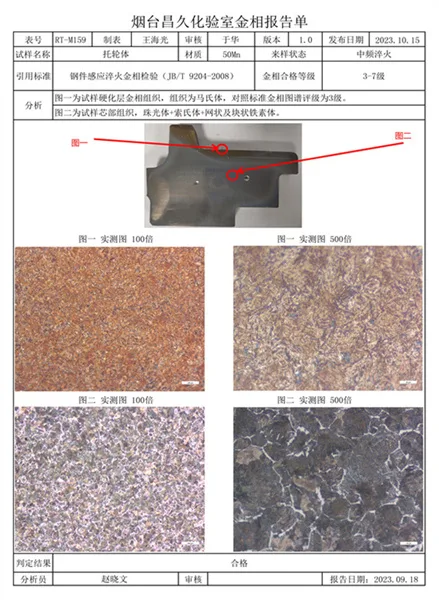

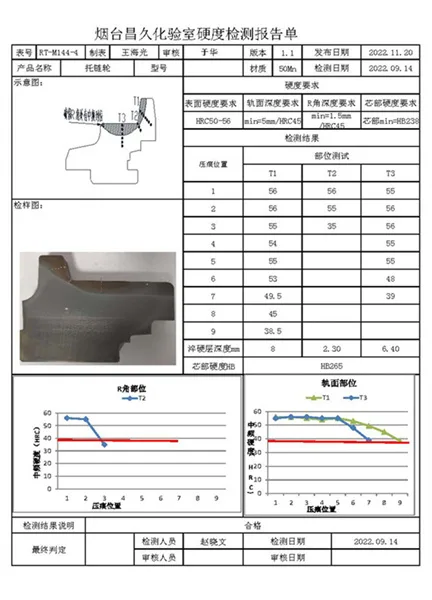

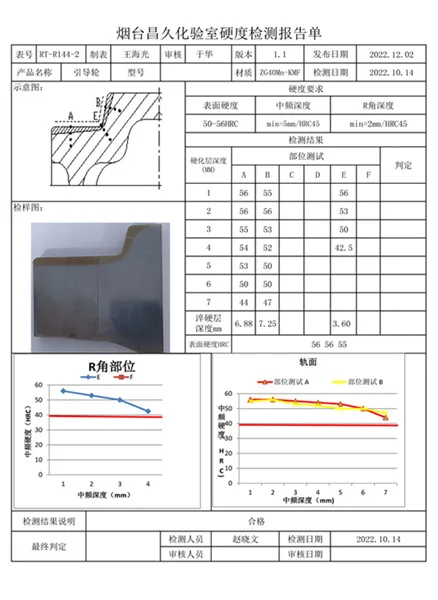

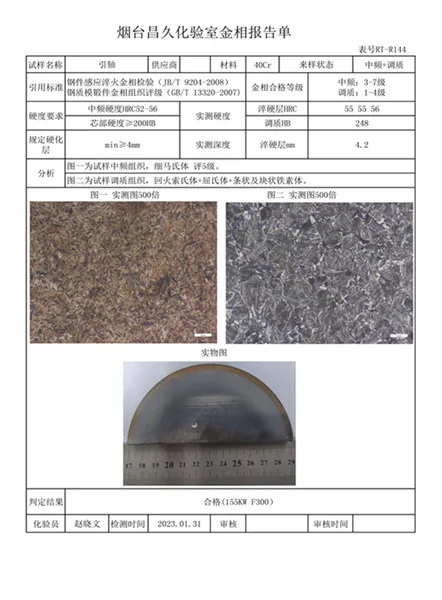

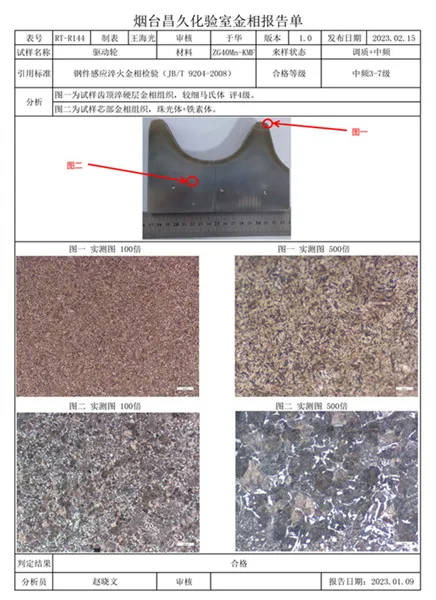

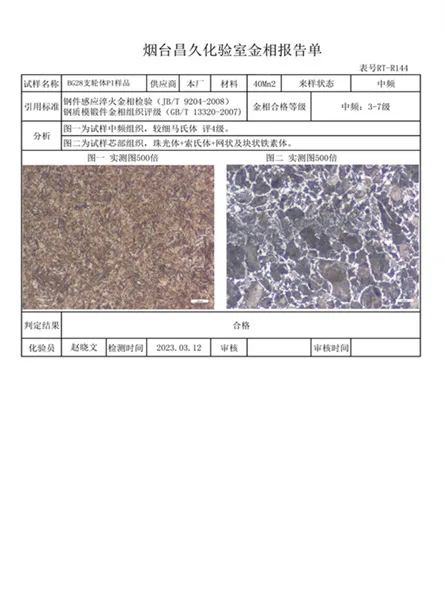

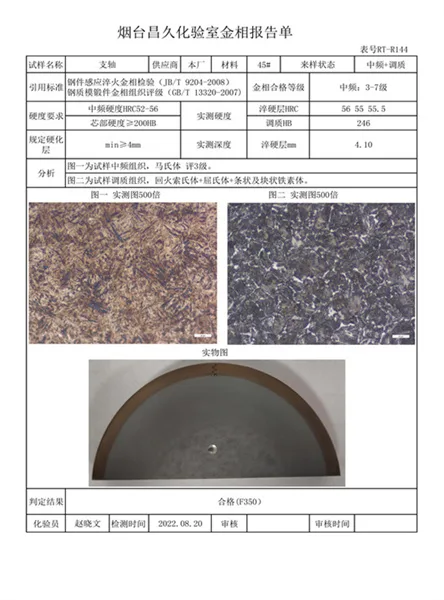

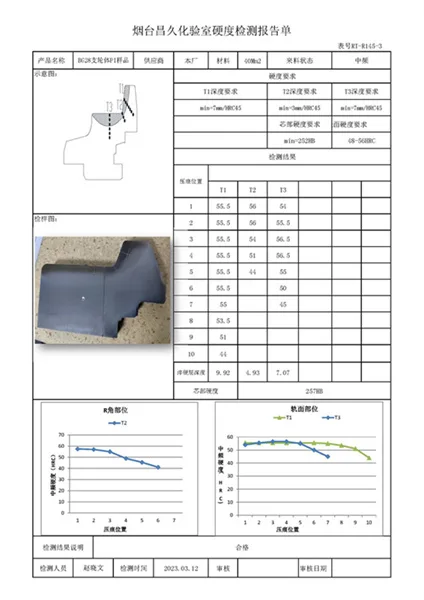

Quality inspection

In terms of quality testing, we are always orientated towards customer satisfaction to ensure that every product meets high standards.

In order to ensure the stable and reliable quality of our products, we use advanced laboratory testing equipment, including metallographic and hardness testing.

We always uphold the principles of integrity and transparency to ensure that our customers can choose our products with confidence.

Request a Quote

Our company has been upholding the concept of energy saving, environmental protection and sustainable development.

Learn More From

Frequently Asked Questions

We aim to supply best quality undercarriage parts for our customer, mainly for Hitachi, Sumitomo, Kobelco, IHI, Nippon Sharyo, Hitachi Sumitomo, Manitowoc, Liebherr, Link-Belt, American, Terex/American, Terex Demag, Ruston-Bucyrus, Lima, NCK, Sany, Fuwa, XCMG, Zoomlion, Sunward, Yutong and so forth brands crane.

Yes, we offer international shipping to most countries. Shipping costs and delivery times depend on your location and order size. Please contact us for specific shipping costs and more details.

We provide detailed product specifications for each item to ensure compatibility. If you are unsure, you can contact our customer service team with your machine model and serial number and we will assist you in finding the correct part.