American 7260 Track Rollers Key Characteristics:

- Type: Lattice Boom Crawler Crane.

- Capacity: Typically rated around 100 tons (90 metric tons).

- Engine: Often powered by Detroit Diesel engines (e.g., 8V71, 6-71).

- Features: Includes main/auxiliary winches, third drum, power load lowering, counterweights, and independent swing/travel.

- Boom: Uses 59S tubular boom sections, with configurations varying in length (e.g., 100ft, 120ft).

- Applications: Heavy lifting in industrial settings, bridge building, and large-scale construction.

Composition:

Lower roller body, Brass Bushing, Shaft, Caps, Floating Seal, O-rings.

Function:

On the American 7260 crawler crane, the track roller (also called bottom roller) is a critical undercarriage component. Its primary function is to support the overall weight of the crane and transfer this load evenly to the crawler tracks and the ground. This ensures stable operation during both traveling and lifting.

Track rollers are installed along the crawler frame to distribute the load uniformly across the entire track system. This reduces concentrated stress on individual track links and helps extend the service life of both the tracks and the undercarriage components.

Another important function of the track roller is to guide and stabilize the track chain. By keeping the track properly aligned with the crawler frame, the rollers help prevent track deviation or derailment and ensure smooth, reliable movement.

Track rollers also reduce friction and wear by allowing the track links to roll smoothly instead of sliding. This minimizes wear between the track chain and the crawler frame, improving efficiency and durability.

In addition, track rollers help absorb impact and vibration when the crane travels over uneven or rough ground. This protects the crawler frame and upper structure while improving overall operating stability.

Technical Details:

| Material | 40Mn2 |

| Place of Origin | Shandong, China(Mainland) |

| Heat Treatment | Whole Quenching and Tempering, then Surface Hardening |

| Advantage | Comprehensive Service System; Professional Research Team; Advanced Production Equipment; Superior Material; Strict Quality Control; OEM Quality |

| Packaging | Export Standard Pallet/ Plywood Case |

| Trade Terms | EXW, FOB, CFR, CIF |

| Technology | Forging |

| Warranty | 2500 Working Hours / One Year |

| Inspection Method | MT, UT… |

| Min Order Quantity | 1 Piece |

| Port of Loading | Qingdao, China |

| Payment | T/T, L/C… |

| Certification | ISO9001 |

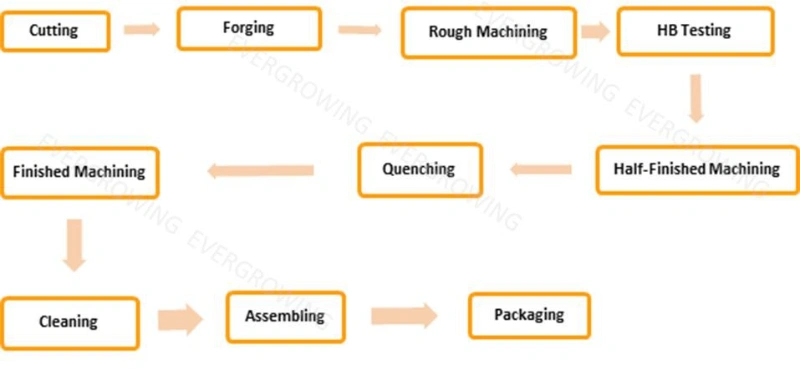

Production Process of American 7260 Track Rollers:

Cutting – Forging – Rough Machining – HB Testing – Half-finished Machining – Quenching – Finished Machining – Cleaning – Assembling – Packaging

Our Market

Our products are exported to all over the world, and have been widely praised by customers.

Reviews

There are no reviews yet.