LIEBHERR LR1700 Crane Bottom Rollers Details:

| Material | 42CrMo |

| Technology | Forging |

| Heat Treatment | Advanced Quenching and Tempering, then Surface Hardness and Deep Hardening |

| Advantage | Superior Material; Strict Quality Control; OEM Quality; Plenty of Stocks |

| Brand Name | EG |

| Warranty | 2500 Working Hours / One Year |

| Crane Tonnage | 700 Tons |

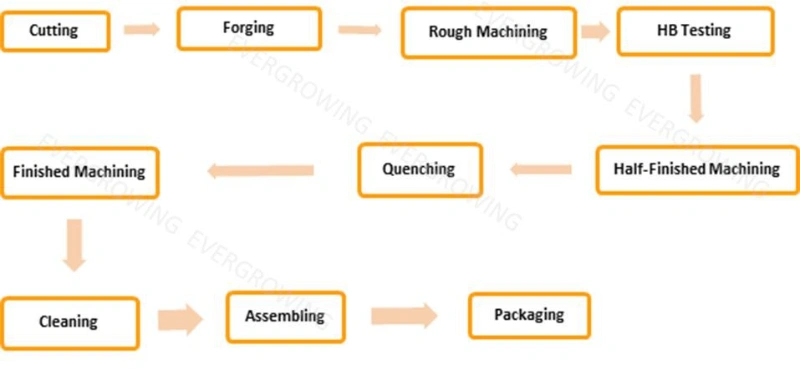

LIEBHERR LR1700 Crane Lower Rollers Production Process:

Cutting → Forging→ Rough Machining → HB Testing → Half-finished Machining → Quenching → Finished Machining → Cleaning → Assembling → Package

Our LIEBHERR Crane Track Rollers Advantages:

- Material is 42CrMo as LIEBHERR Original drawing requirements, to adapt to the heavy load LR1600 conditions.

- Precision machining: the hardness and roughness of support rollers surface need to meet the standard, ensure smooth contact with floor plates and reduce abnormal wear.

- Heat treatment: advanced Quenching & Tempering improve the toughness of the core of the roller body half, and avoid brittle fracture; high-frequency quenching of surface enhance wear resistance.

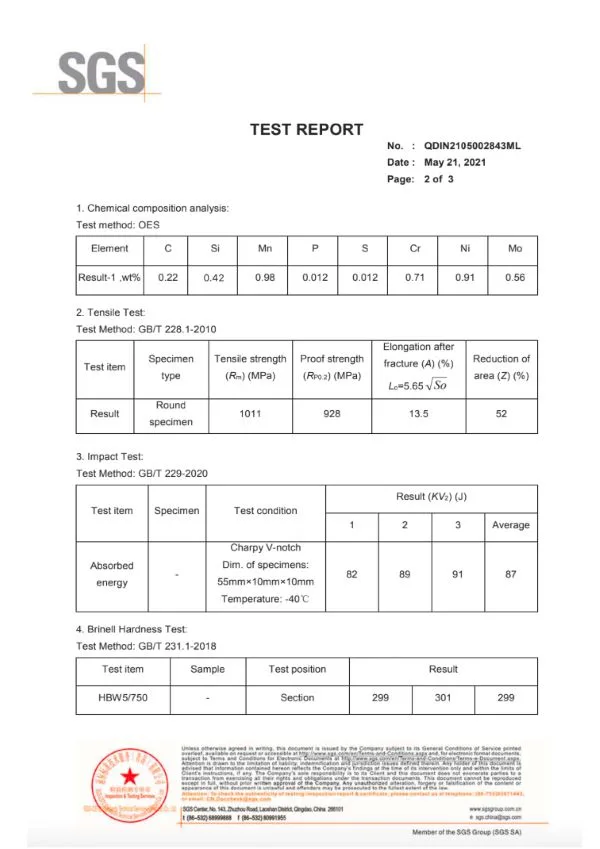

Our Company Certificates:

YANTAI EVERGROWING is Crawler Crane Undercarriage Parts Specialist, such as Track pads, Lower rollers, Upper rollers, Sprocket and Take-up wheel

25+ crane crawler cranes

600+ crane models

5000+ crane undercarriage parts

The parts quality is the first priority for running our business.

If interested, please freely contact us

Mail: info@crawlercranesparts.com

Whatsapp:+86 17853553781

Reviews

There are no reviews yet.