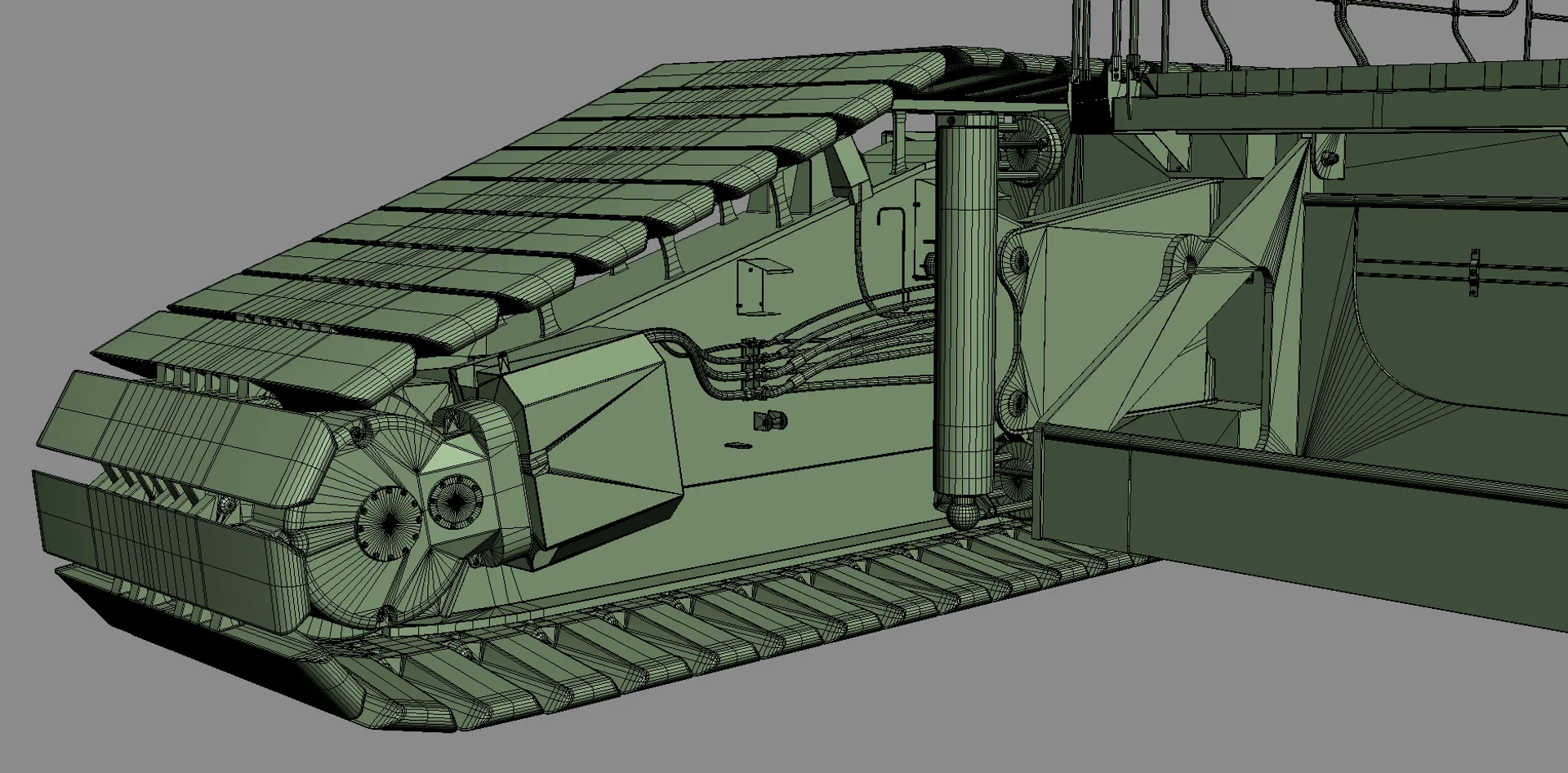

CRAWLER crane TRACK SHOE

Crawler Crane Undercarriage Parts

Crawler Crane Track shoe

We use ZG35SiMn / 28CrMnMo / 28CrMnMoNi and other high-strength alloy steel materials to ensure that the products have excellent abrasion resistance and tensile strength, and are able to be used for a long time in harsh working environments.

Track Shoe/ Track Pad/ Track Plate

We offer a wide range of specifications and models of track plates to meet the needs of different customers, and we can customise the production according to customers’ requirements.

Why choose Our Track Shoe?

Adopting high-quality materials and professional processing technology to manufacture the track plate can withstand large loads and tensile forces to ensure the safe operation of mechanical equipment.

We carry out comprehensive quality tests on each batch of track plates to ensure that the products comply with relevant standards and regulations, and to protect the safety and rights of our customers.

- High Abrasion Resistance

- High Strength

- Deformation Resistance

- Customisation

- Adaptable

- Improved Traction

Benefits of Crane Track Shoe

Our Services

Enhanced Safety

Worn-out or incorrect track shoes pose a dangerous risk to your crew and equipment. Reduced traction and ground clearance lead to unstable travel. Sudden sinking or slippage can cause severe destabilization of the crane. Loose, cracked, or deformed shoes increase the likelihood of derailment. Choosing the right shoes ensures maximum grip without straining crane components. Operators feel confident and secure when traveling on any terrain. Safety should be the top priority when selecting track shoes.

Improved Handling & Control

Smooth and responsive crane operation requires precision in travel. Worn-out shoes hinder control, making travel feel unstable and slippery. Directional changes and climbing become more challenging, requiring extra power and effort. The right track shoes provide a secure connection with the surface, enabling precise and effortless movements. Operators can handle loads with greater accuracy and navigate rough terrain more easily. Shoes designed for specific ground conditions optimize handling.

Increased Capacity & Productivity

Using underrated or worn-out shoes to save money will result in negative consequences. These shoes cannot handle the demands placed on them and may crack or detach, causing the crane to be taken out of service. Any initial savings will be quickly offset by lost productivity and repair costs. By using properly rated shoes that are in good condition, you can optimize lifting capacity and productivity. The crane will stay in operation for longer periods between shoe replacements. This reduces unplanned downtime and allows for the completion of more jobs throughout the year.

Lower Operating Costs

Choosing the correct crane track shoes can save money by reducing maintenance and repair costs, increasing the time between replacements, minimizing downtime, lowering fuel consumption, and extending the life of components. Replacing damaged shoes prevents more significant issues that could require expensive repairs. Shoes specifically designed for your environment last longer before needing to be changed. Using the proper shoes also reduces power drain, resulting in fuel savings.

Supporting Subheading

Our Services

Lorem ipsum dolor sit amet, consec tetur adipis cing elit. Ut elit tellus, luctus nec ullam corper mattis, pulvinar dapibus leo.

One-stop service

We promise to provide you with the fastest reply, the best price, the best quality, and the most complete after-sales service.

Customer Satisfaction

We are committed to delivering high quality services that exceed our clients' expectations. We strive to ensure that our clients are satisfied with our services and work closely with them to ensure their needs are met.

Competitive Pricing

We offer competitive pricing for our services without compromising on quality. Our prices are transparent, and we do not believe in hidden charges or fees.

State-of-the-art Technology

We use the latest technology and tools to deliver high quality services. Our team is well-versed in the latest trends and advancements in technology and uses them to provide the best results.

Quality Assurance

We have a rigorous quality assurance process in place to ensure that all our services meet the highest standards of quality. Our team of quality analysts checks each project thoroughly before it is delivered to the client.

Trust and Worth

Our Brands